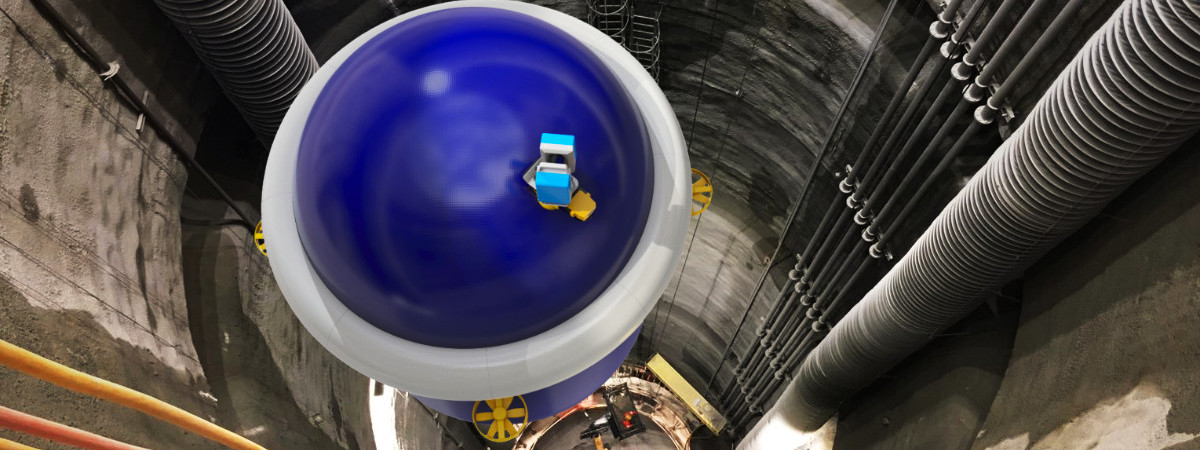

Unleash the power of innovation with our new height access:

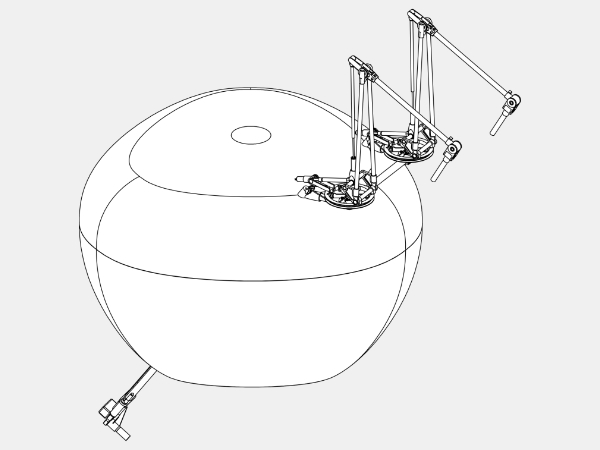

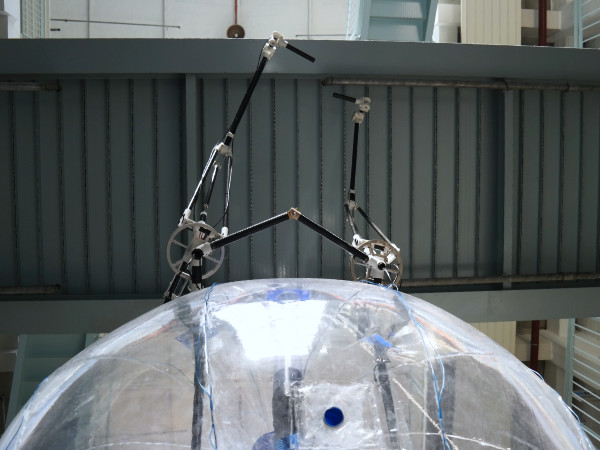

Aerialworker from Aerobotics

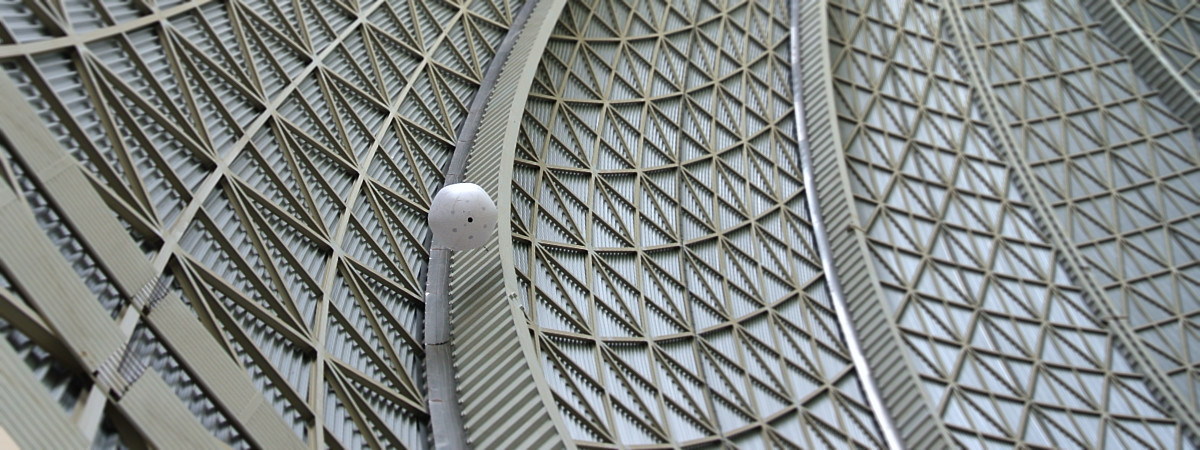

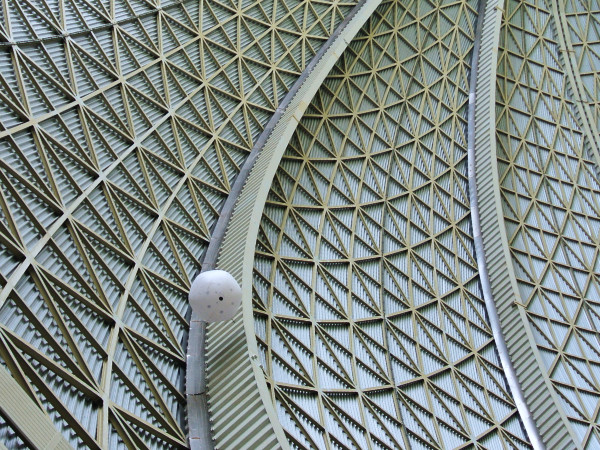

Our two unmanned ballooncopter systems offer unique possibilities for structural investigation and inspection work to support your analysis projects in almost all situations.

Why Aerialworker?

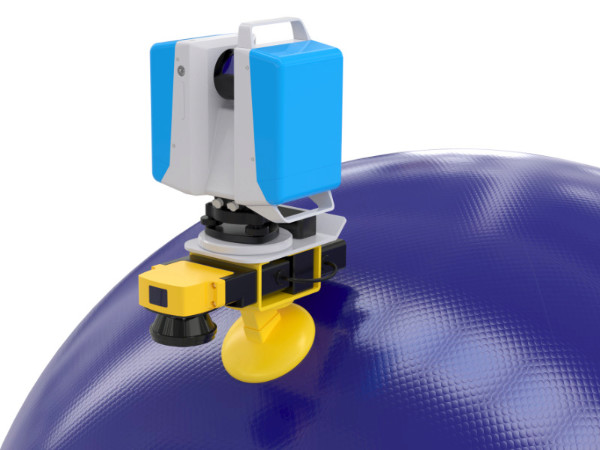

- no dust generation during 3d scanning, photogrammetry or surveying work

- unlimited noiseless operating time

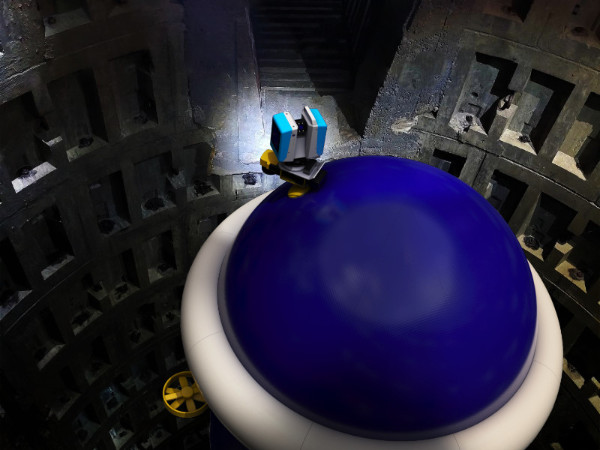

- works in extremely narrow spaces of only 10 m, e.g. on supports or between steel beams

- maximum safety, no falling of equipment or the ballooncopter

- no danger to personnel due to falling

- sustainable due to helium recycling

- no ground load or overflight of installations possible, even during production

- purely mechanical physical stabilization system to prevent tipping, tilting or yawing

- short assembly and disassembly times

- high safety standard - no additional systems required

- no floor load, overflight of installations or during production

- environmentally friendly (effort, energy, noise)